Handling of components with a balancer for a welding robot

- Lukas Kaiser

- Apr 22, 2021

- 2 min read

Updated: May 13, 2024

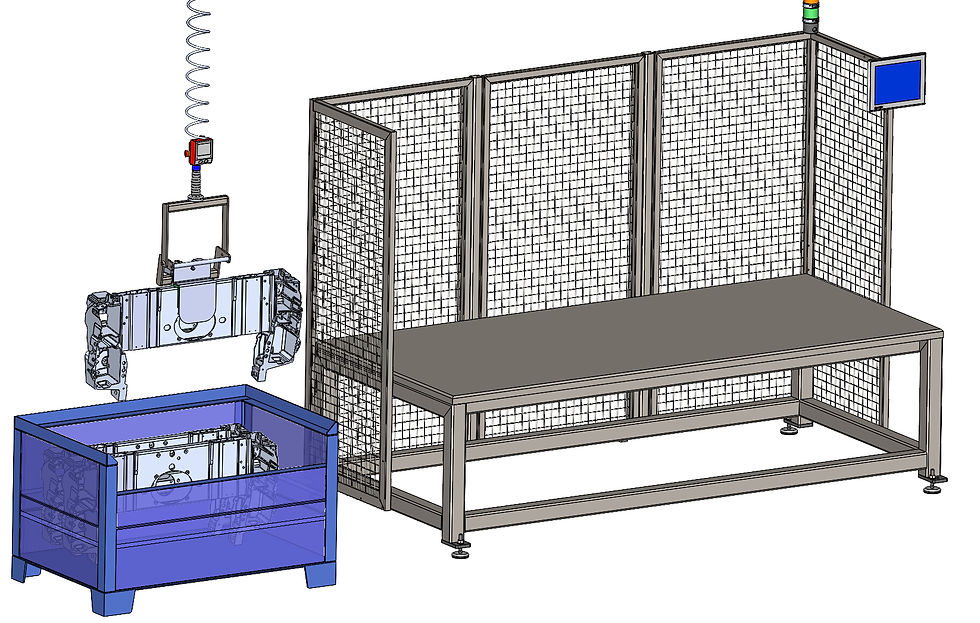

When sensitive products need to be handled, assembled or joined with positional accuracy, the use of the ezzFLOW balancer from Best Handling Technology is recommended. This intuitive handling system adapts perfectly to the user and his activity. Since the balancer keeps the workpiece suspended, the operator can focus on his full concentration on his activity and precision.

In an application on a welding robot, this method of operation has proven its worth.

1st work step

The machine operator inserts small, lightweight individual parts into the clamping device of a welding robot. This operation is performed manually.

2nd work step

The clamping device is rotated into the shielded area of the welding robot. At the same time, the finished part of the previous work cycle is rotated from the shielded area into the area of the machine operator.

3rd work step

Now the machine operator must remove the finished part from the clamping device and first place it in a measuring device. After successful measurement, the finished part is removed again and deposited in a container.

In these activities, a bulky and heavy component must be handled precisely: a case for the ezzFLOW. Precision is a must, because the component must neither bump against the measuring device (for it could be damaged) nor must the component be damaged.

The ezzFLOW can be perfectly adapted to such applications. With the possibility of programming acceleration, deceleration, returns and speeds, directly on the display on site, the ezzFLOW offers maximum flexibility. There are no jerky movements during the lifting and lowering process and the run is vibration-free.

The ezzFLOW is available in two different versions:

All variants of the ezzFLOW are equipped with optimized load handling devices according to customer requirements for the respective task.

Balancer ezzFLOWpneumatic as an aid for manual handling and as a drive unit

In addition to its widespread use as an aid for manual handling, the ezzFLOWpneumatic is also the core of Best Handling Technology automation solutions as a drive unit. It is very fast due to its pneumatic control and is particularly suitable for repetitive operations.

The automation or partial automation system with pneumatically driven linear axes is an alternative to 6-axis robot solutions. It is characterized by simplicity and robustness. The system weight of a linear axis solution for handling 40 kilo is in the range of 200 kilo, depending on the design, while a corresponding robot solution weighs one ton.

Comments